Garage Interlocking Garage Tiles Facts & Fiction

Garage Interlocking Tiles: Facts & Fiction

The truth about hollow-core vs. solid PVC tiles — and why the US Army chose ArmorGarage.

Hollow Core vs. Solid Core — The Difference Is Everything

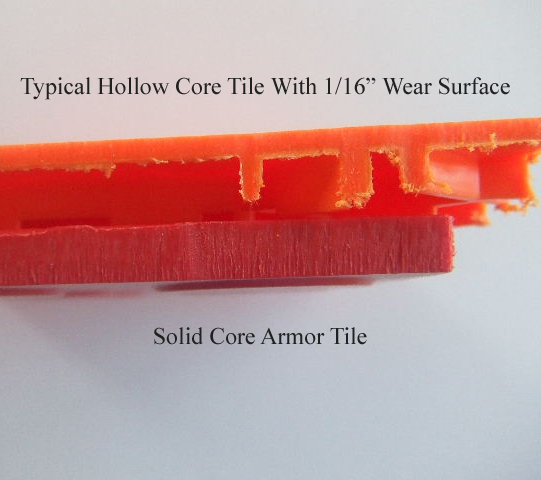

In the image below it's easy to see the difference between a typical hollow-core polypropylene tile and our solid PVC tile. Why is that an issue?

Hollow-core polypropylene tile (top) vs. solid PVC ArmorGarage tile (bottom)

✗ Hollow-Core Peg & Loop

- Just a few flimsy connectors around the perimeter

- Tiles split apart, heave, and develop wear indents

- Click-clack noise walking and driving — "tile rattle"

- Only 1/16" wear surface on vertical ribs

- Weighs under 1 lb per tile

✓ ArmorGarage Solid PVC

- Continuous T-Joints all around every tile

- Knock together with rubber mallet — they stay together, won't shift or develop seam gaps

- Silent — no click-clack, no tile rattle

- Up to 5/16" solid virgin PVC throughout

- Weighs up to 5.5 lbs per tile

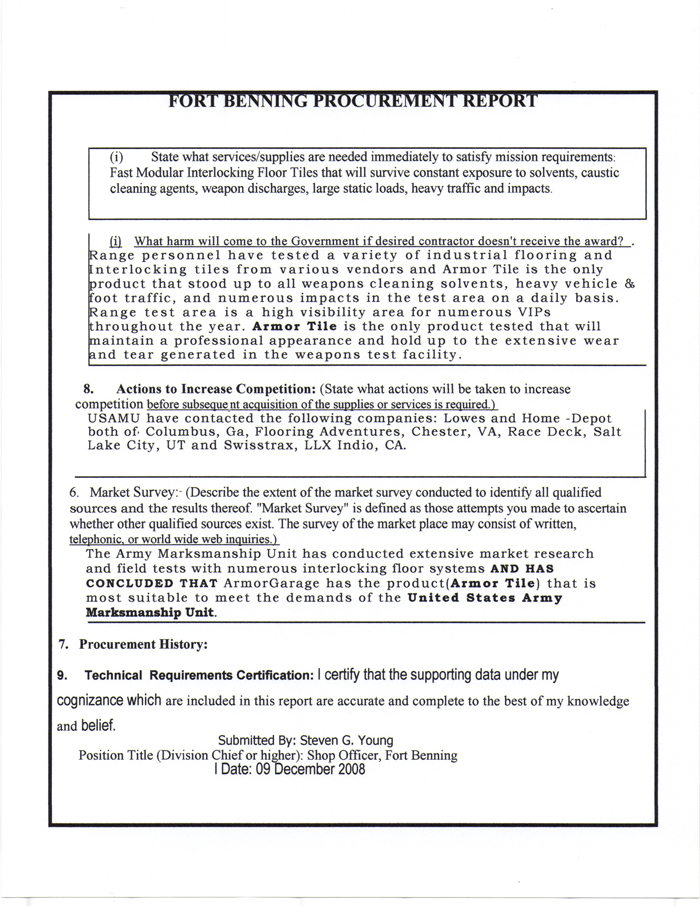

Rated #1 by the US Army

ArmorGarage Interlocking Garage Floor Tiles were rated best by the US Army. Out of all the tiles the Army tested, they decided to purchase our tiles based on overall performance during their torture testing — not based on which tile was cheapest.— Fort Benning Procurement Report

Fort Benning Procurement Report Document

If buying the cheapest price tile or popular brand name is your main criteria, we think you're making a big mistake. Even though the hollow tile is made with only a quarter of the material our tile uses, and that material costs a quarter of the price per pound versus our PVC — they sell for not much less than our tiles. Pretty easy to see which is the better value.

The Problems with Hollow-Core Polypropylene Tiles

As a seller of garage tiles, we have no preference as to what type or style of tile we sell — only that it is problem-free. The tiles we make and sell have performed over the years with no problems for our customers. Problematic tiles, such as the hollow-core peg & loop tiles we used to sell, were removed from our product offerings many years ago.

Be suspicious of any website dispensing expert advice about installing Porcelain Tiles or carpeting on a floor with vehicle or heavy rolling traffic.

Noise: The "Popcorn Machine" Effect

Hollow-core tiles are stiff and brittle. When you walk on them, they make a very cheap-sounding click-clack noise. When you drive over them, the pegs pop in and out of their corresponding loops — your floor sounds like a popcorn machine.

Some articles advise placing fabric mats underneath to deaden the sound. This just becomes a sponge for all sorts of nasty things. Can you imagine what that fabric looks and smells like after a few years under leaky garage floor tiles?

The constant popping in and out of connectors causes them to eventually fail. As they start to fail, you'll see a shift in your tile floor and widening gaps between tiles. Suddenly you have grout lines in your plastic-tiled floor.

The "Air Circulation" Myth

They also say hollow-core tiles let air and water flow through underneath, whereas solid tiles do not. But one of the important reasons you install tiles is to protect your concrete slab — the idea is to minimize dirt and fluids from getting under the tiles in the first place.

Our close-tolerance interlocking T-joints run continuously around the entire tile, keeping debris from getting underneath — way better than any Peg & Loop joint ever will. And once you put in a fabric mat under your tiles, the tiles embed into the fabric, cutting off any so-called circulation.

Cracking: The High & Low Spot Problem

Being so stiff and brittle, polypropylene tiles cannot bend and mold themselves to the contour of the floor like solid PVC tiles do. This creates stress points where your slab has a high or low spot.

No concrete floor is perfectly flat — there are always high and low spots that aren't perceptible normally. But place a flat, stiff, brittle material over it and you'd see it teeter-totter over a high spot, which eventually becomes a break point. We all know what happens to any material when it's bent up and down continuously in the same spot. It's not a matter of if — it's just a matter of when it breaks.

Strength & Durability: The Real Test

Hollow polypropylene tiles are nothing more than a sheet of brittle plastic 1/16" thick glued onto a set of vertical ribs. The notion that you can store cars on jack stands is ridiculous. Or use hydraulic jacks or store heavy objects with small hard plastic wheels. That 1/16" tile surface will form indents under heavy small-footprint loads or heavy static loads.

It's not the roll-over capacity that counts — it's the static load capacity. There's no comparing the static load capacity of a solid PVC tile to a hollow-core tile. You're not supporting the Hook & Ladder fire apparatus on its outriggers with Peg & Loop tiles!

Fire truck on ArmorGarage Heavy Duty Coin Tile floor — try that with hollow-core tiles.

We've seen one article stating you can install a car lift over hollow plastic tiles and bolt the lift through the tiles into the concrete. No one in their right mind would or should ever think of doing that.

The Hammer Test: Take a hammer and beat on our PVC tile and any hollow Peg & Loop plastic tile and see what happens. You'll have a hard time causing damage to one of our tiles. Not so with the hollow plastic tile.

As far as perforated tiles — let's just say it's not a good idea unless you're a commercial car wash. The idea is to prevent as much fluid and debris from getting under your tile floor as possible, not to encourage it.

Frequently Asked Questions 15

PVC is the highest grade of material used for interlocking floor tiles. ArmorGarage Tiles are extruded from 100% pure virgin PVC — very few manufacturers use it, and most who do mix in recycled and cheap filler materials. Polypropylene and Copolymers are used to make water bottles and food containers — no comparison to PVC. Although they may look similar, they are not nearly as strong, flexible, or durable. Each Armor Tile is up to 5/16" thick solid PVC, weighs up to 5.5 lbs, and is the only tile guaranteed for life. Look at the wear surface, not total thickness — hollow-core tiles give you only 1/16" of wear surface. Tiles are priced per square foot; please add 5% for cutting waste.

It is true for hollow-core peg & loop type tiles. They make a cheap hollow click-clacking noise as you walk over them, and when you drive your car over them they produce a continuous rattle from the pegs and loops popping in and out of each other. You can purchase hollow-core tiles with rubber plugs and grommets to deaden the sound, but then you end up with inferior tiles that cost much more than our higher quality tiles. ArmorGarage solid PVC tiles are silent.

No preparation is really needed — just sweep the floor clean and remove any lumps of concrete or other materials. The tiles are flexible enough to follow the contour of your floor. We suggest starting from the center front row and working your way back. You'll have cut tiles at the back and side walls. We recommend cutting the locking tabs off the front edge where you'll install the ramp edging. Use any good floor tile adhesive for the ramp edging only. Use a rubber mallet to knock the tiles together.

Tile removal is as easy as installing them — just pop the tile out. You can drill a small hole to aid in prying the tile up without damaging adjacent tiles. If you move, you can easily take your floor with you. ArmorGarage Tiles are often used as temporary flooring over fine finished flooring such as hardwoods, granite, and marble.

This is not an issue with ArmorGarage Tiles. Snow melt will eventually leak through, but simply rinsing the tiles with a good amount of water will flush out any accumulated salts. Our tiles are 100% mold & mildew proof, impervious to road salts, any type of vehicle fluids, and just about any other chemical. They really are just about indestructible.

No. ArmorGarage Tiles are flexible enough to conform to the contours of your floor without creating voids underneath that become future failure points — unlike copolymer and polypropylene tiles that are brittle and stiff. Hollow-core tiles are prone to cracking at high and low points because no garage floor slab is 100% flat and level.

A two-car garage can typically be installed in a few hours. No adhesive is needed — adhesive is used only when forklift traffic will be making sharp turns and sudden starts and stops. We suggest simply sweeping the floor clean. The beauty of ArmorGarage Tiles is that they cover all your floor's blemishes and will last a lifetime.

Yes. Email us a sketch with the dimensions of your floor and the colors you'd like. We'll email you back a list of products and a description of what you'll need. You can fine-tune it as desired.

Yes. With a load capacity of 100,000 lbs per tile, you can park any vehicle on it and use most contractor equipment. Car lifts can sit on the tile or have the tile cut around the base. We don't recommend placing industrial machinery such as a 50-ton hydraulic press or 100-ton stamping machine on them — tiles should be installed around that type of machinery.

Mild soap and water is all that's needed. Armor Tiles are stain resistant so they clean very easily. A sponge squeegee works great on them also. We also recommend coating the tiles with Hillway Direct Floor Maintainer & Sealer to protect them from tire rubber leaching stains.

ArmorGarage Tiles are up to 5/16" thick solid PVC with interlocking tabs. ArmorGarage Mats are roll-out polyvinyl sheets about 1/8" thick, available in 7.5', 8.5', and 10' widths in any length up to 60' long. Both are lifetime guaranteed.

Not necessary, but not a bad idea. A little Liquid Nails under the ramp edging and part of the first row of tiles is what we recommend to lock the floor in place.

All materials expand and contract. ArmorGarage Tile's PVC construction expands and contracts less than copolymer tiles. If you install in summer, install tight to the wall — they'll contract about 1/4" in winter. If you install in winter, leave a 1/4" gap for summer expansion. In a year-round conditioned area, no expansion or contraction will occur. Seal the gap along walls with flexible caulking or cover with standard base molding.

Any type of power saw works fine — circular saw, table saw, jig saw, or Sawzall. ArmorGarage Tiles cut quickly and smoothly with regular sharp wood-cutting blades.

Yes, but we strongly suggest ordering the Flat style tiles. They offer a smooth surface for steel-wheeled carts, bins, dollies, and other production vehicle traffic. Check with us to see if your application will require gluing the tiles down.

TO SEE ALL OUR GARAGE FLOOR TILES GO TO MAIN GARAGE FLOOR TILES PAGE

For Additional Help And Service. Call us at Toll Free 866-532-3979 Or Email Us: info@armorgarage.com.